Using 3D Scanning and Digital Twin Technology to Support Facility Expansion

In 2021, Liscio’s Bakery, a family-run business based in southern New Jersey, was looking to expand production operations to support their rapidly growing business. Over the years, the bakery had scaled up from the small storefront opened in 1994 to multiple retail locations and a 100,000 square foot production facility in Glassboro, New Jersey. As demand continued to increase, the company was looking for new and efficient ways to manage its production equipment and grow their Glassboro facility by another 30,000 sq. ft.

That’s where SAM’s 3D services came in. The bakery’s desire to design and construct a new shipping area, while upgrading how they managed production was a perfect application for SAM’s 3D documentation technology.

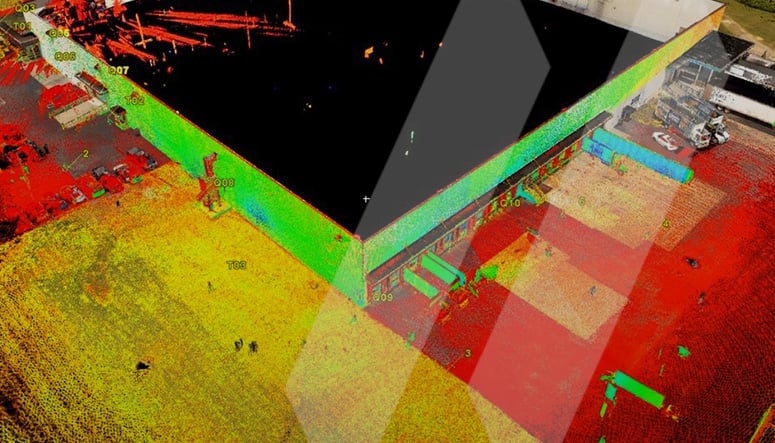

Our Building Information Modeling (BIM) team met with the leaders of Liscio’s Bakery and laid out a plan to capture the facility utilizing 3D laser scanning as well as photographs to digitally recreate the existing conditions and create a three-dimensional and photogrammetric true digital twin of the facility. Once the 3D and photogrammetric mapping were complete, asset information could be streamed live and attached to this model. The bakery operations team would then be able to instantly visualize things like oven temperature or the state of valves on the digital twin of the facilities.

After reviewing the advantages of this approach compared to traditional surveying, the owners of Liscio’s Bakery were on board, and our team got started.

Using a combination of the new NavVis Slam instrument and Leica 3D RTC360 Laser Scanners, our team documented the interior and exterior of the manufacturing building. After this documentation phase, a 3D model was created to implement digital facility management. The SAM team met with Liscio’s team and reviewed the ideal methods for utilizing the Point Cloud and model, as well as the next steps in linking existing equipment data streams facilitating the management of operations, and ultimately the design and construction of the expansion of the facility.

Creating a digital twin empowered the owners of the bakery to make informed, intelligent decisions on their investment. When the owners of Liscio’s began their expansion, they had the ability to create a timeline and a schedule based on the exact conditions of the facility. During the design and construction phase, the digital twin provided easy access to hundreds of inspection-grade photos, on-demand, with SAM’s exclusive online documentation platform. In addition, with the real-time information integrated into the 3D world, when the owners sought a loan to fund their expansion, they were able to present the bank with an analysis of the entire facility.

Chris Zmijewski, SAM’s Vice President, BIM Service Lead, and Office Manager lead the data collection and analysis of this project. “The partners and bakery owners of Liscio’s are very forward-thinking in the expansion and incorporation of the most advanced technologies into their business,” said Mr. Zmijewski. “They see the opportunity to leverage the 3D documentation into a true digital twin model for both asset management and for future analysis of capital investments for their operations.”

We were excited to serve as a strategic partner to help this multi-generational, family-owned business continue to grow by utilizing our state-of-the-art photographic documentation service. Moving forward, Liscio’s Bakery has a cost-effective way to monitor the state of their equipment, visualize their space, and find intelligent solutions to any manufacturing challenges they will face.