How Automated 3D Visualization Benefits Bridge Asset Inventory Projects

| Carlos Montoya

The collapse of the I-35W Bridge in Minneapolis in 2007 confirmed that human visual inspections are often unreliable and urged authorities to develop more accurate methods for evaluating the condition of the nation’s aging infrastructure. Moreover, the frequency and intensity of hurricanes like Harvey, Irma, and Maria in 2017 pressed the need for taking proactive measures to prevent significant damages during extreme weather events. Methodologies that incorporate the advancements in technology and data processing are crucial for the development of resilient infrastructure. That said, automated 3D visualization provides great benefits for bridge asset inventory on roadway projects.

In the United States, a complete visual inspection of all components of a bridge structure to determine their physical and functional conditions is usually required every 24 months. Inspectors need to be on-site actively involved for tasks such as observation, data collection, data analysis, or decision-making. Human visual evaluations are expensive and time-consuming. These evaluations also represent a safety risk to the human inspector as bridges are large and complex structures often located in harsh environments. Reaching and accessing many critical regions for viewing the structure represents a major challenge.

According to the National Bridge Inspection Standards (NBIS), bridge inspectors assign integer numerical condition ratings from 0-FAILED to 9-EXCELLENT based primarily on a visual comparison of the as-is structure to a hypothetical new structure. The ratings reflect the functional conditions of decks, superstructures, and substructures. Functional parameters of bridges, including advanced cracking, corrosion, section loss, deterioration, spalling, or scour, could be detected from imagery data to assist bridge inspectors in determining functional conditions in a safe and cost-effective manner.

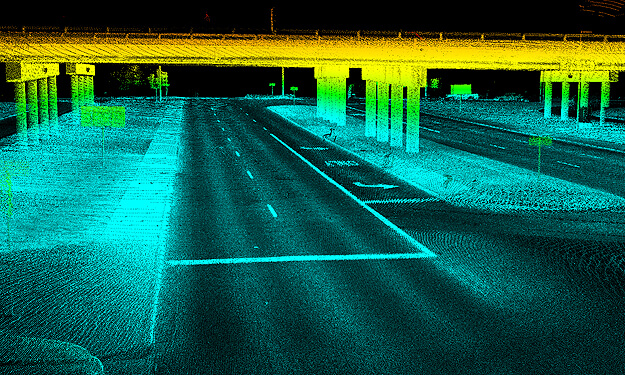

Advanced and efficient tools that allow authorities to inspect bridges for maintenance, repair and rehabilitation (MR&R) activities are vital. Visual inspection methods were automated at first with the advent of video camera technology. The most recent advances include systems that integrate laser scanners with high-resolution cameras. There are many systems commercially available to capture the physical attributes of bridges; however, the right tool or integration of tools is crucial to obtain quality data. A multiplatform approach (e.g. Unmanned Aerial Systems-UAS, boat) can be explored in order to acquire imagery data for viewing critical regions of bridges. Remote sensing systems with the ability to fully support 3D infrastructure visualization and measurement dramatically reduce risk, labor costs, and time for bridge inventory. Under constrained budgets, the importance of having automated workflows to address the infrastructure maintenance needs of large bridge inventories cannot be overemphasized.

After data is acquired in the field, engineering professionals need raw data to be transformed into useful information to determine the condition of the structure. Custom workflows, software tools, IT infrastructure, and data hosting solutions are needed to accomplish this task. Transportation authorities need accurate, quality data to optimize MR&R activities and budgets.

I have been involved in the successful delivery of numerous asset attribute inventory projects for State, Federal, and municipal clients. These inventory projects have provided useful information to transportation agencies for data driven asset management planning. At the moment, I am working on a project to deliver a bridge clearance program for the Texas Department of Transportation (TxDOT). The current task order requires delivery of clearance values for 4,448 bridges throughout the State of Texas. We are completing the project by acquiring mobile LiDAR and imagery on these 4,448 bridges. It is estimated that over 150,000 unique features will be extracted and delivered from the mobile mapping data. In order to successfully deliver the project, we customized a technical approach.

Furthermore, adding Artificial Intelligence (AI) in the processing of bridge inspection imagery can provide the ability to automatically detect functional parameters of bridges. This could develop into an automated technique for localization of bridge damage regions of interest that will directly enable robust, vision-based, numerical condition ratings of bridges needed for prioritizing and scheduling MR&R activities.

Innovation drives efficiency and allows SAM to develop and provide the best solutions possible. SAM can employ innovations developed for current/past projects and has the capability to develop new innovations to facilitate data driven project planning for the transportation sector. To learn more about SAM’s high tech project integration tools that can enhance bridge data delivery contact Carlos Montoya at Carlos.Montoya@sam.biz.

Carlos Montoya

Carlos Montoya, Ph.D. joined SAM in 2020 and has 13 years of engineering, aerial mapping, and project management experience. His expertise includes transportation and geotechnical engineering, LiDAR, photogrammetry, and mobile mapping.

View Profile