Cost Savings from 3D Transportation Datasets

| Carlos Montoya

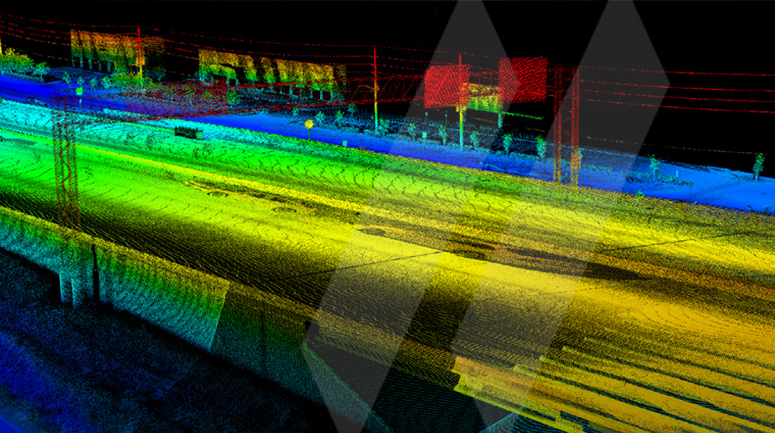

The transportation industry is using 3D data in a growing number of applications related to survey, design, and construction. 3D models reflect the engineer’s design concept in areas typically not defined in 2D plans or cross sections (e.g. intersections). 3D models also create an improved visualization tool for engineering analysis (e.g. sight distance) and facilitate coordination with other design disciplines. With these 3D models, contractors are delivered a high-quality product that provides an accurate project footprint related to earthwork and construction limits.

Developing 3D models results in overall cost savings through the design and construction process, they also provide a smooth transition from design to construction. The designer has greater flexibility and functionality with 3D model tools, as they can shift from designing in cross sections to designing in a continuous surface. Important changes that occur between cross sections are easily identified in a continuous surface. Calculations for quantity take-offs and projects requiring earthwork/grading operations (e.g. new locations of roadways, widening, and interchange reconstructions) are more accurate and precise. 3D models increase overall productivity and detect design issues more quickly. The future includes 5D design that incorporates time and costs. The practice of digital twins will encompass all design and construction elements and will one day provide near real-time tracking and monitoring of the complete life cycle of a transportation project.

Remote sensing data facilitates the development of 3D models for transportation projects. The rapid advance of mapping technologies (laser sensors, cameras, position/navigation systems) and data processing software have made it possible to generate accurate and detailed 3D data of transportation infrastructure. The accuracy and detail offer an opportunity to manipulate datasets for different purposes, which means cost savings for projects across the transportation industry. The demand for manipulating and re-purposing data is expanding, mainly because the data available to analyze is rapidly growing. Data is translated to provide the link between data function and domain areas. Algorithms and tools extract information and present it in a format that fulfills the specific needs of a project.

Transportation datasets can be re-purposed for numerous applications. For example, mobile mapping asset inventory projects are frequently conducted (approximately every 2 years), hence DOTs need current and accurate information of the location and condition of highway assets to maintain regular operation of the highway system. Features to be extracted for these types of projects could include paint lines, roadside signs, overhead signs, bridge clearances, images of bridge entrances showing posted sign height, and guardrail inventories and classifications. As DOTs acquire statewide asset inventory data, engineering projects may develop. Asset grade data from inventory projects can be transformed to design grade data for engineering projects. Design grade data would be suitable to support additional transportation and infrastructure engineering design projects such as bridge and roadway design, rutting analysis, resurfacing, utility relocates and clearances, paint striping condition and quantities, right of way (ROW) acreage to be mowed, guard rail heights, and billboard compliance.

Improved accuracy adjustments (asset grade to design grade) at SAM are easily performed due to the utilization of design-grade, dual-scan mobile mapping systems and innovative data calibration techniques. By implementing these innovative calibration techniques, inventory datasets can be post-control to both survey control and existing high-accuracy remote sensing datasets. As engineering projects develop, previously collected mobile data can be calibrated to survey control. Now, 3D modeling of bridges, jersey walls, curbs and mapping for the roadway and overhead structures is accomplished from existing data. Single scanner systems and non-survey grade dual scan systems cannot produce data quality and density required for engineering design, especially driving at highway speeds. An integration of advanced data processing tools and hi-tech scanning systems allows for re-utilization of transportation datasets.

Large datasets require a better level of data interchange and better software development structures to enable specific user applications. A flexible software environment is important, as many engineering firms and transportation agencies work with the most popular software packages like Autodesk and MicroStation. It is critical to work with software specialists to ease data portability to the next level (engineer).

At SAM, we focus on integrating, loading, processing, and transforming data from external sources for exploratory data analysis and visualization. Data is transformed for survey, design, and construction of transportation infrastructure, as well as applications related to asset management, maintenance activities, and operational decisions. One dataset, numerous applications.

Numerous applications usually represent challenges related to time, money, and software. SAM is continuously collaborating with leading equipment manufacturers and software specialists to develop cost-effective solutions for the transportation industry.

Carlos Montoya

Carlos Montoya, Ph.D. joined SAM in 2020 and has 13 years of engineering, aerial mapping, and project management experience. His expertise includes transportation and geotechnical engineering, LiDAR, photogrammetry, and mobile mapping.

View Profile